Paduan Nikel 20 (UNS N08020) /DIN2.4660

| Paduan | unsur | C | Si | Mn | S | P | Ni | Cr | Nb+Ti | Fe | Cu | Mo |

| Paduan 20 | Menit |

|

|

|

|

| 32.0 | 19.0 | 8*C |

| 3.0 | 2.0 |

| Maks. | 0.07 | 1.0 | 2.0 | 0.035 | 0.045 | 38.0 | 21.0 | 1.0 | kasaimbangan | 4.0 | 3.0 |

| Status Aolly | Kakuatan regangan Rm Mpa Menit. | Kakuatan ngahasilkeun RP 0.2 Mpa Menit | Pemanjangan A5 % minimum |

| Dipanaskeun | 620 | 300 | 40 |

| Kapadetang/cm3 |

| 8.08 |

Batang, Batang, Kawat sareng Bahan Tempa- ASTM B 462 ASTM B 472, ASTM B 473, ASME SB 472, ASME SB 473,

Pelat, Lambaran sareng Strip- ASTM A 240, ASTM A 480, ASTM B 463, ASTM B 906, ASME SA 240,

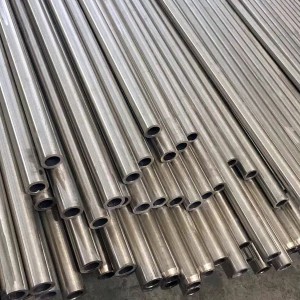

Pipa jeung Tabung- ASTM B 729, ASTM B 829, ASTM B 468, ASTM B 751, ASTM B 464, ASTM B 775, ASTM B 474,

Anu sanésna- ASTM B 366, ASTM B 462, ASTM B 471, ASTM B 475, ASME SB 366, ASME SB-462, ASME SB

Résistansi korosi umum anu saé pisan kana asam sulfat

Résistansi anu saé pisan kana retakan korosi setrés klorida

Sipat mékanis sareng kamampuan fabrikasi anu saé

Presipitasi karbida minimal nalika ngelas

Unggul dina tahan korosi kana asam sulfat panas